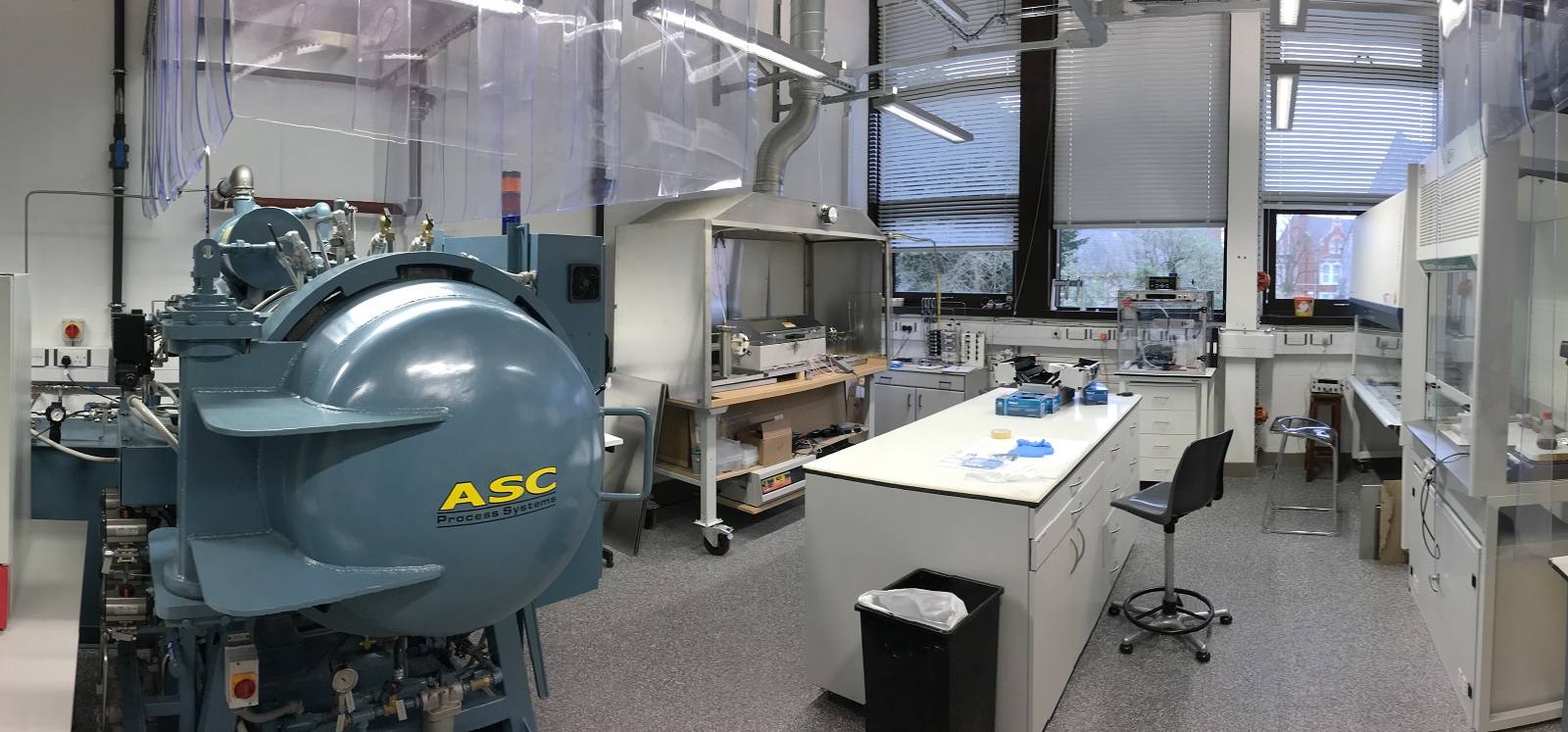

Facilities

The Advanced Composites Research Group has state-of-the-art facilities:

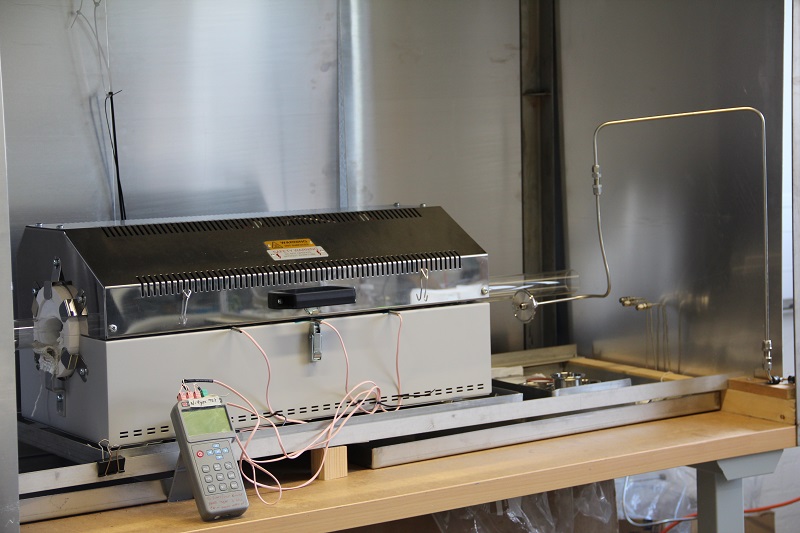

High temperature PID-controlled furnace and reactor (to 106 mm dia) with full suite of reactive and inert gases for the production of high specification carbon nanotubes (CNTs)

The ACRG combines leading-edge composites research with leading-edge research in the production and exploitation of carbon-based nanomaterials, where each seamlessly informs and enhances the other. The CVD capability can produce the uniquely useful ‘directly drawable and spinnable’ CNTs to make webs and yarns.

Professor Stephen C. Hawkins - Contact Person

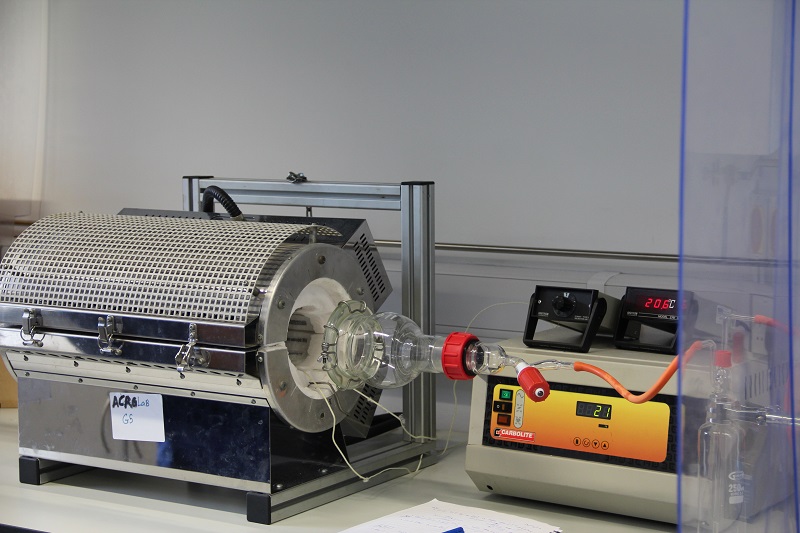

Low-pressure high-temperature system for gas-phase surface modification

Surface modification of carbon nanomaterials and composites enables improved interfacial interaction and mechanical performance. The Advanced Composites Research Group operates a low pressure / vacuum furnace that efficiently functionalises surfaces in a gas phase with minimal physical disruption to the material morphology and minimal waste.

Professor Stephen C. Hawkins - Contact Person

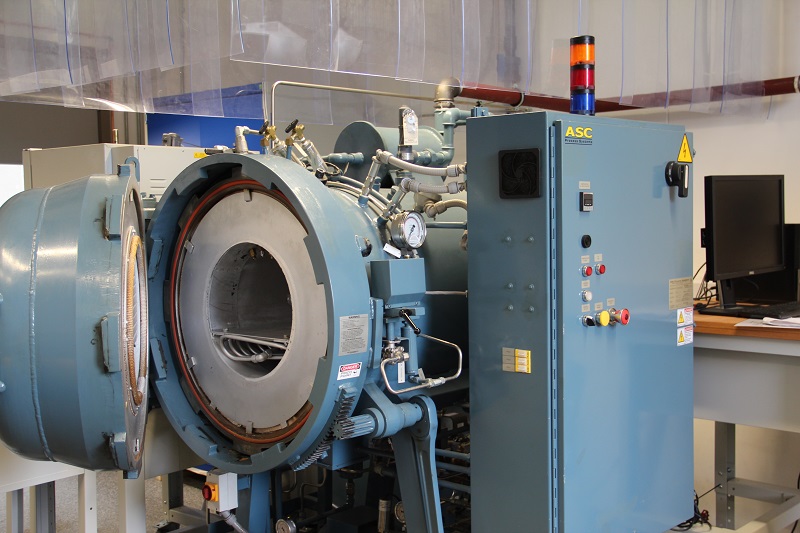

High temperature, high pressure autoclave for resin infusion and thermoforming of thermoset and thermoplastic composite fabrication

The Advanced Composites Research Group operates a fully computer-controlled ASC Autoclave rated to 425 °C and 14 bar for research into high specification composites that utilise both thermoset and thermoplastic resins, and provides access to industry for developmental research.

Dr Zafer Kazanci - Contact Person

Microplasma system for liquid phase surface modification of nanomaterials to study dispersion and interaction behaviour

Room temperature atmospheric pressure plasma. Application include surface functionalization of nanomaterials, in situ synthesis of novel nanomaterials/hybrid structures for advanced functional applications (e.g. biomedical, sensing, etc).

Dr. Dan Sun - Contact Person

Non-destructive inspection tool for capturing A/B/C-scan data

More details coming soon

Professor Zafer Kazanci - Contact Person

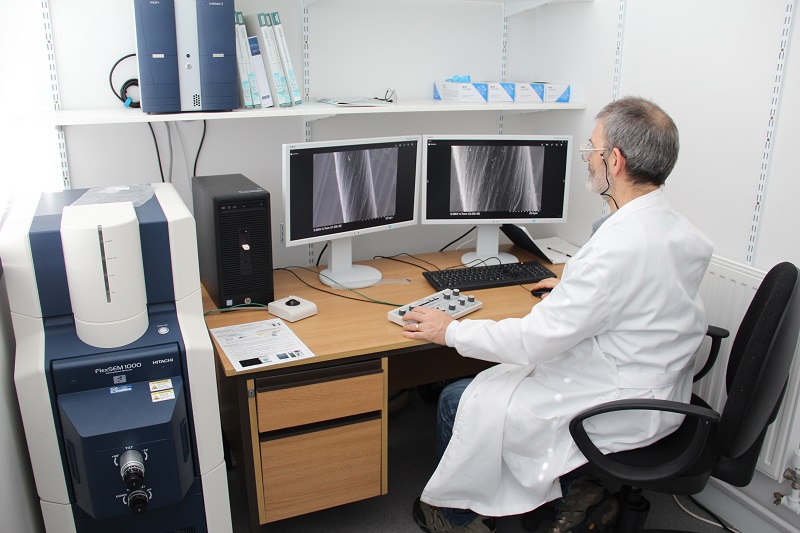

Scanning electron microscope with secondary electron backscatter, energy dispersive spectroscopy, low/high voltage, low/high vacuum capabilities for structural and compositional analysis

Staff and students within the Advanced Composites Research Group have available, for hands-on operation, a state of the art SEM especially selected for its suitability for direct study of polymers, composites and sensitive materials. Fully optioned with BS, SE and EEDS, this machine is an invaluable tool for research and publication.

Dr. Savko Malinov - Contact Person

A wide range of mechanical testing equipment for assessing material performance under static, dynamic, fatigue, and tension-compression loading

More details coming soon

Professor Zafer Kazanci - Contact Person

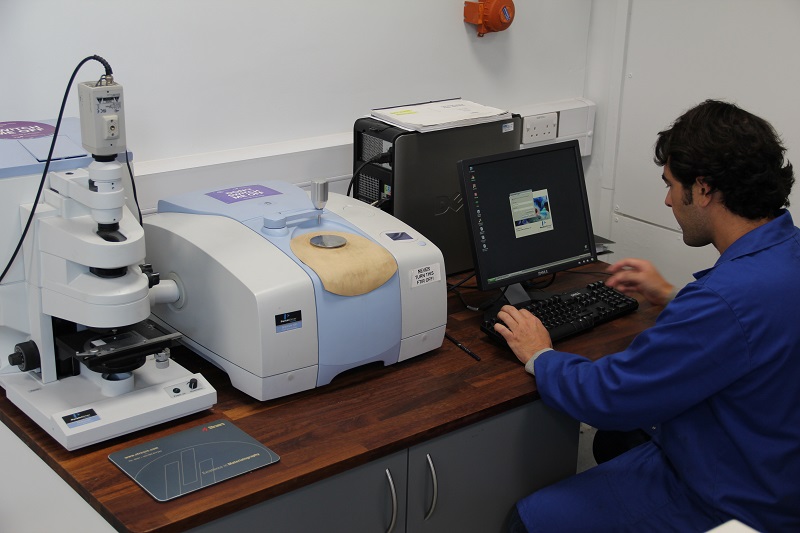

Fourier transform infra-red spectroscopy (FTIR/FTIR-ATR)

The surface chemistry of the materials (polymers, composites, carbon nanostructures and their modifications) can be studied by means of FTIR spectroscopy (Spectrum 100 FT-IR Spectrometer, Perkin-Elmer). This equipment can analyse the materials in the common transmission or reflection mode, using the Attenuated Total Reflection mode device (ATR).

Professor Stephen C. Hawkins - Contact Person

Capability for the determination of thermal properties (i.e. melting points, cure profiles, glass transition temperatures, and crystallisation temperatures) of polymers and its nanocomposites

More details coming soon

Professor Stephen C. Hawkins - Contact Person

More specifications coming soon

11 measurement functions: DC voltage & current, True RMS AC voltage & current, 2- and 4-wire resistance, frequency, continuity, diode test, capacitance and temperature. In addition, it has 0.015% DCV accuracy, multiple connectivity options – USB 2.0, Serial Interface (RS-232) and GPIB and up to 50,000 memory points for data logging.

Dr Zafer Kazanci - Contact Person

Detection of newly synthesized materials, quantifying analyte concentration, measurement of films and optical components.

More details coming soon

Dr Zafer Kazanci - Contact Person

For sample separation and purification.

More details coming soon

Dr Zafer Kazanci - Contact Person

More specifications coming soon

This instrument is a highly accurate digital 4 input thermometer and data logger for working with any K, J, E, T, R, S, N, L, U, B and C-type thermocouple as temperature sensor. It has independent input setup, memory and read function (99 sets), 512 KB auto data logging capacity and USB interface.

Dr Zafer Kazanci - Contact Person

High resolution infra-red video / still camera and accessories

Temperature plays an important role in advanced composites, be it in their processing, performance or applications. The Advanced Composites Research Group has ready access to a high-resolution video / still camera and associated accessories when needed to advance research and development in this realm.

Dr. David Thornhill - Contact Person

3-D printing for prototyping, research and development in continuous carbon, aramid and glass fibre composites

The two 3D Printers are used to create one-off devices and prototypes, to study novel structural geometries, and to validate numerical models using continuous carbon, aramid and glass fibre reinforced thermoplastics. This capability complements the very extensive facilities of Queen’s Polymer Processing and Research Centre.

Dr. Zafer Kazancı - Contact Person

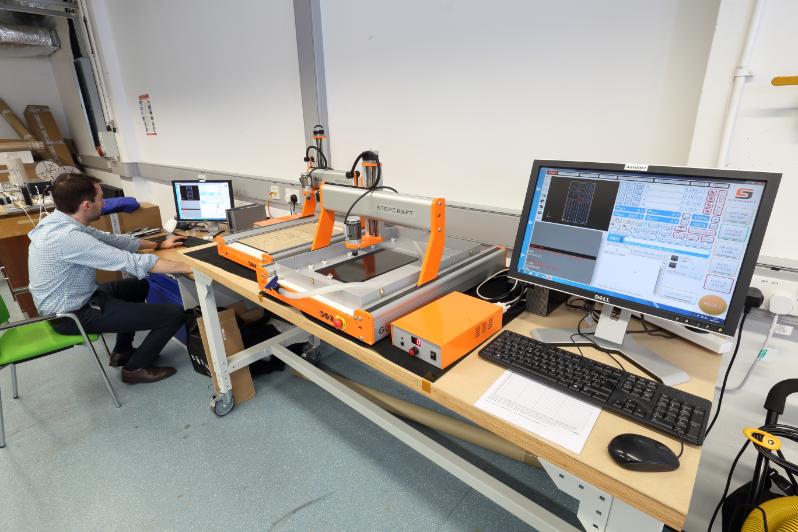

Three-axis CNC milling machines equipped for precise cutting of composite and polymer materials

Experimental testing of composite materials in the Advanced Composites Research Group requires precisely machined specimens to be made on a frequent basis. Material sheets can be machined quickly with repeatable results, and little wastage.

Mr. Denis Dalli - Contact Person